Waterflooding is the most widely used fluid injection process in the oilfield, as it’s a cost-effective and proven technique for increasing oil recovery.

The reservoir was discovered in 1967, followed by development and first production in 1970. Water flooding began in 1974 based on injection wells patterned as radial-oriented spokes and peripherally at the oil-water contact.

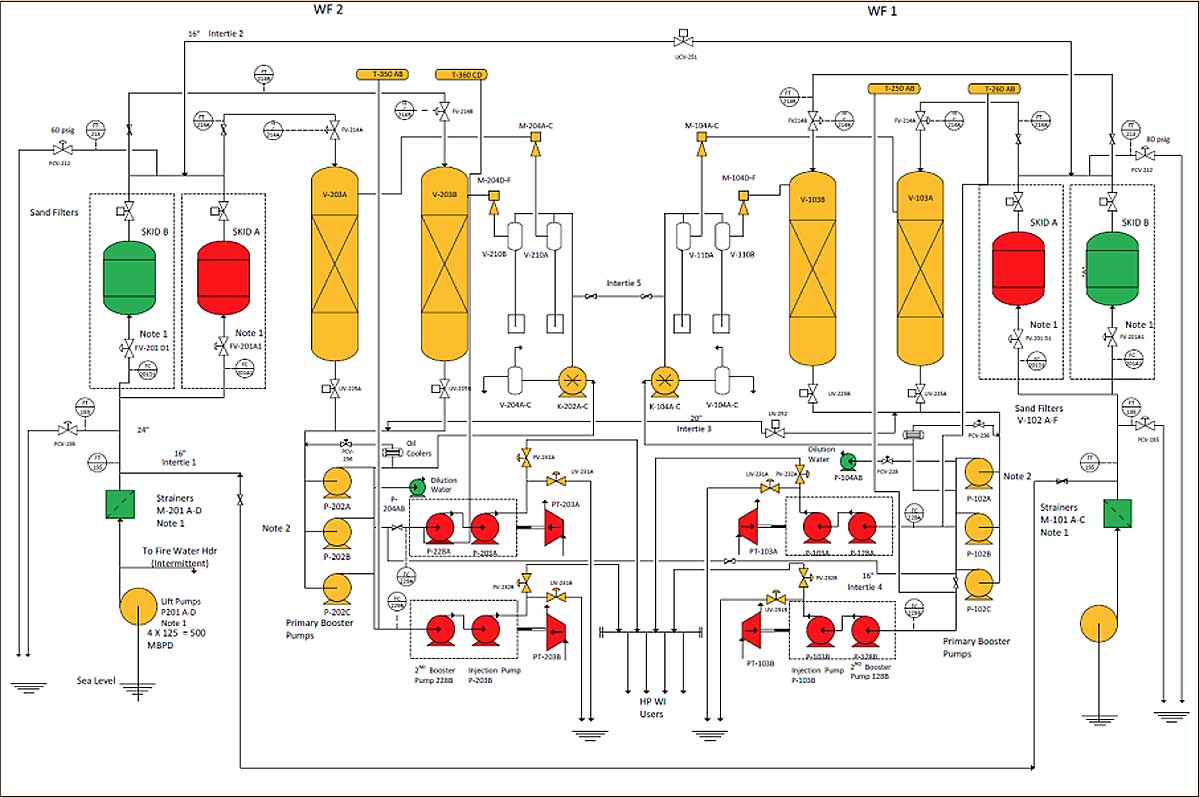

Our waterflood facilities are designed to deliver filtered, deoxygenated seawater under sufficient pressure to facilitate secondary oil recovery. The total throughput of our waterflood facilities is running through four parallel trains. Pressurised processed seawater is injected into reservoirs through water injection wells in satellite platforms.

At any time four high-pressure injection water pumps are working. These pumps discharge high-pressure water to a distribution header linking four trunk lines via a subsea pipe network to wellhead platforms.

The process is inter-tie at lift pump discharge, sand filter discharge, Vacuum tower outlet and Primary booster discharge to operate the plants independently in Single Mode or as one plant in Duel Mode.

Fig. DPE Offshore Waterflood Process Diagram