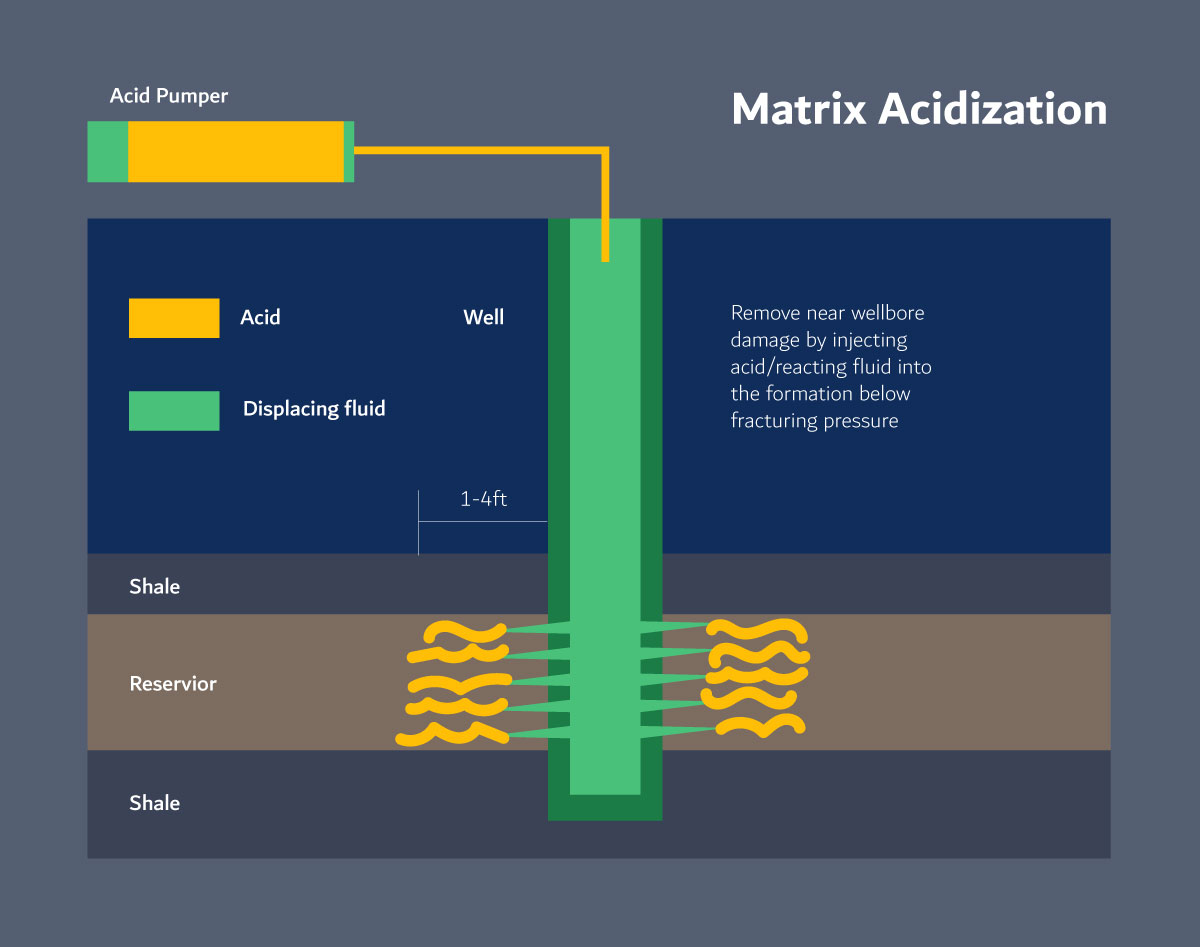

We have long employed matrix acid stimulation to increase the performance of oil, water or gas wells by removing the near-wellbore damage, that is the natural byproduct of drilling and production operations. Every stimulation job is unique and is influenced by certain factors.

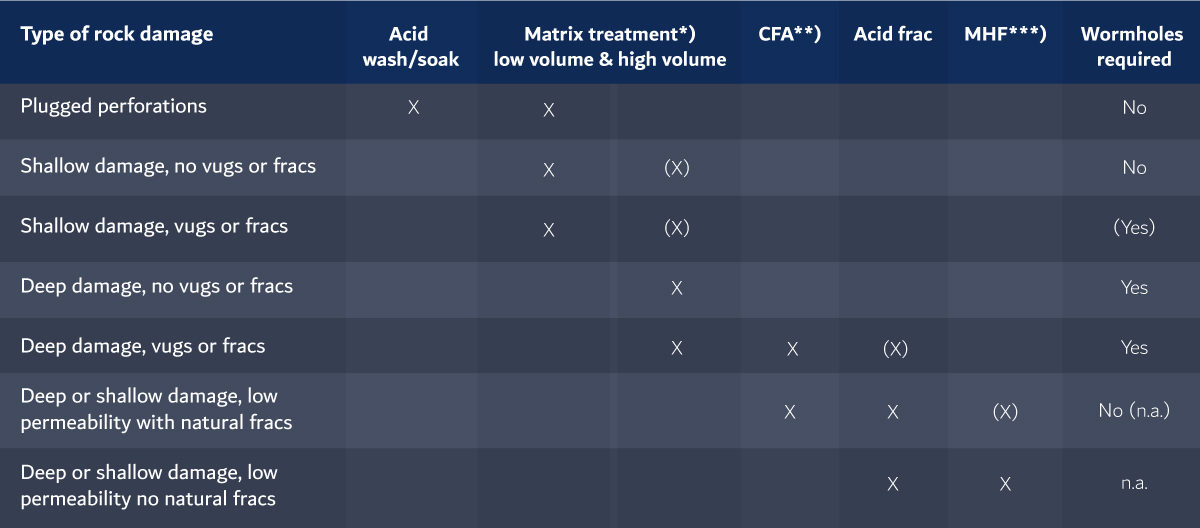

Over the years, carbonate acid treatments have been designed to target stimulation of the hydrocarbon zone through the removal of near-wellbore damage and the resulting wormholes. When considering ‘mature high-water-cut’ fields, successful stimulation treatment involves reviewing the good history, reservoir characteristics, and potential production results before selecting the optimum stimulation treatment.

Placement strategy and diversion techniques lie at the heart of any matrix stimulation treatment design. They are the two key considerations when trying to achieve the objective of uniform liquid penetration throughout the entire section or into each natural fracture system. The danger is that full production will be negatively affected if complete coverage is not achieved.

We practice a number of placement and diversion techniques, that include:

Many of these techniques are not used in isolation. For example in long horizontal sections, our team will utilise a combination of the above methods, like coiled tubing for placement in conjunction with foamed fluids for diversion.

Fig. IPTC-13203-MS “Case Study of Successful Matrix Stimulation of High-Water-Cut Wells in Dubai Offshore Fields”

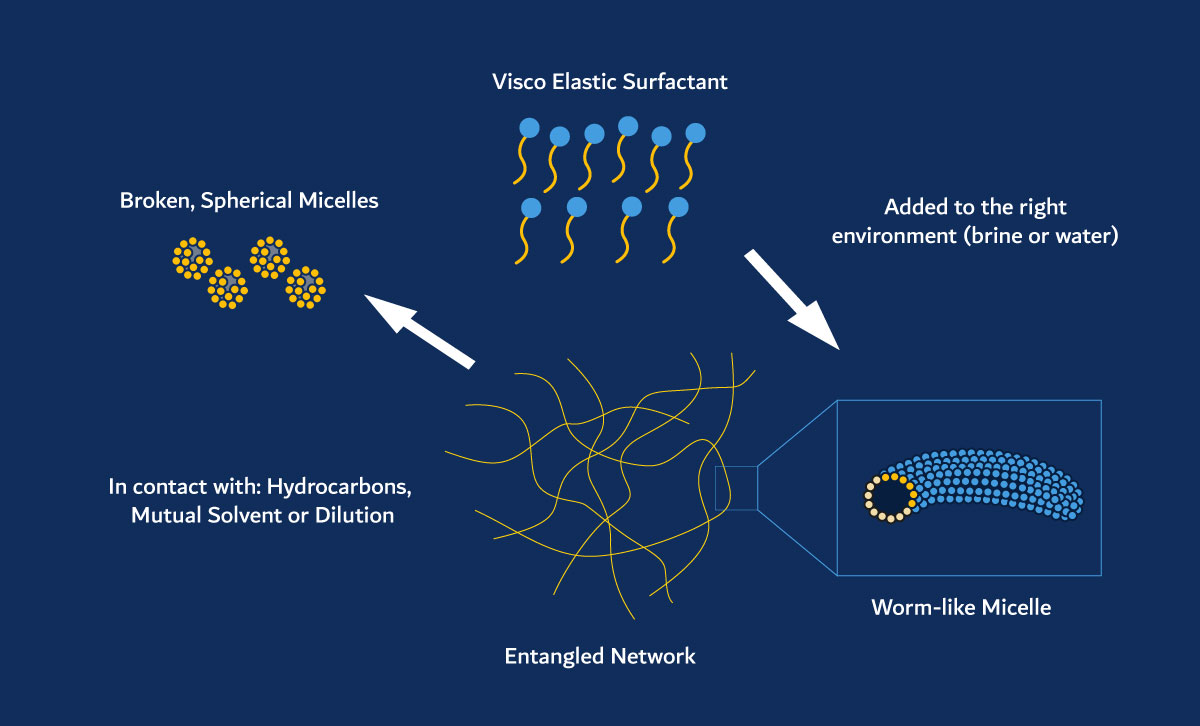

Fig. Mechanism of viscoelastic surfactants building viscosity

Fig. IPTC-13203-MS “Case Study of Successful Matrix Stimulation of High-Water-Cut Wells in Dubai Offshore Fields”